Wireless Systems Integration for Geotechnical Monitoring

Monitoring of tailings facilities will always play a vital role in the safety of waste management at mines. More so, the importance of fully functional readout units and accurate data regarding the health of the waste storage facility can mean the difference between safe and unsafe operations.

In early 2023, the Terra Monitoring team were contracted to assess and evaluate the integrity of various piezometers and data loggers installed at a tailings storage facility in the Mpumalanga Province in South Africa.

Upon arrival to site, the Terra Monitoring geotechnicians’ first course of action would be to assess each piezometer and datalogger to isolate any faulty equipment. After each test was conducted, the team concluded that one of the installed datalogger units sustained some electrical damage as it displayed signs of an overload probably caused by a lightning storm in the area.

When it comes to data logging, the industry has seen many advancements in technology in recent years. Some of the current and more older systems require technicians to manually read the data collected at each collection point. This can be a very tedious task to perform regularly. For this reason, the team proposed the installation of a wireless reporting system. With a wireless system, mine engineers will have the ability to receive real-time data regarding the stability of the facility, and they can receive SMS warnings should the logged data indicate an area of concern. In turn, engineers would also have received an instant notification as soon as the unit went offline.

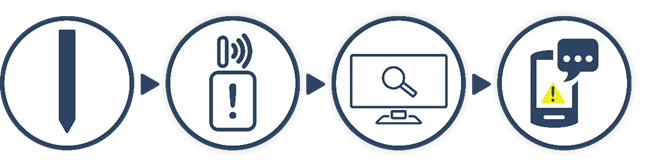

- The installed piezometer is connected to the wireless data logger.

- The datalogger sends the received data wirelessly to the control room.

- The data is then processed at the control room and can then send alerts via SMS to the designated engineers.

- Readout data is available instantly and eliminates having to record data manually at each point.

- Data recording intervals are adjusted remotely.

- The system can be configured to warn engineers of anomalies in the data.

- The infrastructure can aid with the future planning of the facility.

- Long-term monitoring with little maintenance.

- Each unit is powered by battery, solar or main power.

Contact us for more information.

Plot 28 Central Road

Sunrella, Lanseria

Gauteng

South Africa

Tel. +27 (0)861 436 632

Email. info@geogroup.co.za