Geotechnical Investigation for Dam Wall Repairs

In June 2023, Geomech Africa was awarded a project to conduct a geotechnical investigation on a collapsed dam wall at Lonehill Park and Dam in Johannesburg. After heavy rainfalls experienced in mid-2022, the pedestrian bridge and dam wall collapsed resulting in heavy water loss due to the rising water pressures.

The Geomech Africa team mobilised to the site on the 10th of July 2023, led by supervisor Elija Mahlangu. The directive was to perform geotechnical drilling on 5 holes of which 1 was inclined. The team did this by means of drilling 26mm holes to 15 meters each and 1 vertical hole to 29 meters using YWE D90R drill rigs designed and manufactured in-house.

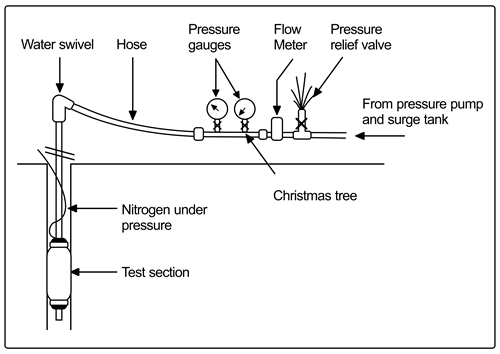

The GeoGroup In-situ testing team had to conduct Lugeon tests, otherwise known as packer testing, on the holes. A Lugeon test is an in-situ testing method used to estimate the average hydraulic conductivity of rock mass. The test is performed by measuring the volume of water taken in a section of a test hole when the interval is pressurized at given pressures. This test is primarily conducted in variably permeable formations under evaluation of fracturing. The recorded results provide us with much-needed information about the hydraulic conductivity of the rock mass, including the rock matrix and the discontinuities.

The test is conducted in a portion of a borehole isolated by pneumatic packers. The water is injected into the isolated portion of the borehole using a slotted pipe which, itself, is bounded by the inflated packers. The packers can be inflated using a gas compressor on the surface so they can isolate and seal that portion of the borehole. A pressure transducer is located in that portion to measure the pressure with the help of a reading station on the surface.

Firstly, a maximum test pressure (Pmax) is defined so that it does not exceed the in-situ minimum stress, thus avoiding hydraulic fracturing of the rock mass. The test is carried out at five stages of pressure. This is done by increasing and decreasing pressure between zero and maximum pressure. At each stage, constant pressure is applied for an interval of 10 minutes while pumping water. Water pressure and flow rates are measured every minute. Using the average values of water pressure and flow rate measured at each stage, the average hydraulic conductivity of the rock mass can be determined.

Our teams had to be attentive, and safety-minded, as the park is still a public space for surrounding residents and their pets. They ensured that a safe workspace was maintained, and the supervisor was close by should residents have any questions.

The project was completed within a week and on time with no reported accidents or incidents.

Plot 28 Central Road

Sunrella, Lanseria

Gauteng

South Africa

Tel. +27 (0)11 966 7760

Fax. +27 (0)86 663 3896

Email. info@geogroup.co.za